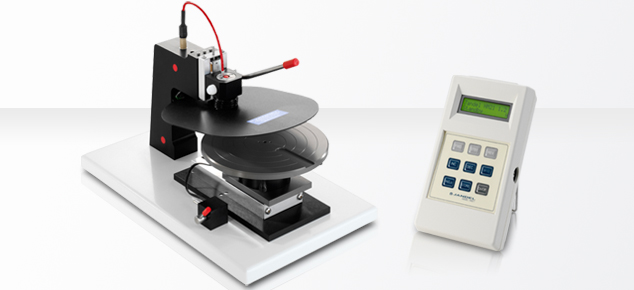

The Multiposition Wafer Probe combined with the HM21 Hand Held Meter Test Unit provides a high quality, easy to use system for measuring the sheet resistance and/or volume resistivity of wafers up to 200mm (8″) in diameter.

The Multiposition Wafer Probe has the ability to probe 1, 5, 9, or somewhat more positions on multiple wafers with 1mm positioning repeatability from wafer to wafer. It is not motorized, but requires that the user moves the wafer stage by hand. It is available with either a 6″ (150mm) wafer chuck or an 8″ (200mm) wafer chuck.

The price is the same for either unit, however, the MWP-6 would be preferable for use with wafers that are 6″ in diameter or smaller due to the increased ease of centering the wafer on the wafer chuck. Annular rings (not vacuum rings) allow wafers to be centered more easily. To aid in centering smaller wafers, the 6″ Multiposition Wafer Probe has circular patterns on the wafer chuck with diameters of 25mm, 50mm, 75mm, 100mm, and 125mm.

The 8″ system has circles at 125mm and 150mm. The Multiposition Wafer Probe can be connected to a vacuum source for wafer hold-down. The instrument comprises a white powder-paint coated metal base carrying a Delrin column supporting the vertical slide, operating lever shaft, and micro-switch. The vertical slide carries the probe head, secured by a clamp screw. The probe head is positioned so that the micro-switch does not pass current until the probes have made contact, lost motion ensures that the current is switched off before the probes are raised. The wafer table slides towards the operator to enable the wafer to be centrally positioned, after which the vacuum control valve can be operated to secure it in position.

When the table is pushed to the limit of its travel, a measurement can be made at it’s center. Four radial positions at right-angles are denoted by a spring-loaded index ball incorporated in the rotary table. The radial distance of measurement is denoted by a similar arrangement on the linear slide index plate. Unwanted settings can be blocked off by easily removed screws. So that, for example, one could choose to measure at the center and four points at 50mm radius. A grounded metal shield screens the wafer from light and electrical noise during measurement. It is arranged that the shield rises when the probe head is fully lifted to permit loading.

The system incorporates the Jandel Cylindrical probe head which is built to high standards of quality and accuracy.

Multiposition Wafer Probe Specifications:

Wafer Chuck – Hard anodized aluminum alloy with vacuum hold, centering grooves, and tweezer notch for: 6″ model – 3″, 4″, 5″ and 6″ wafers, 8″ model – 5″, 6″, and 8″ nominal diameters.

- 6″ Model Preset Measurement Positions: Center and four radii at right angles 15, 20, 25, 35, 50, and 60mm

- 8″ Model Preset Measurement Positions: Center and four radii at right angles 32, 38, 50, 57, 68, and 94mm

- Services: Vacuum line or pump required

- Dimensions: 355 x 215 x 195mm high

- Net weight: 6″ model – 3.5kg, 8″ model – 4.0kg

| Sampling Plan C, ASTM F-81-89, using MPW-8″ | ||

| Wafer | 1/2R | 6mm from edge |

| 5″ | 32mm | 57mm |

| 6″ | 38mm | 68mm |

| 8″ | 50mm | 94mm |

The Jandel HM21 Hand Held Meter is a battery powered four point probe meter which includes a universal AC power adaptor so that it does not have to run on batteries when portability is not important. The Jandel HM21 is a portable current source / meter specifically designed for the four point probe measurement technique. For successful measurements the HM21 supplies a constant current and displays either the resultant voltage or the sheet resistance in ohms/square depending which function has been chosen.

The sheet resistance measurement range is 1 ohm/square up to 10 Megohms/square (in practice you can measure down to around 0.01 ohms/square, but the accuracy may be compromised slightly). This equates to a bulk (or volume) resistivity range of approx. 0.01 ohm.cm to 100 Kohm.cm. The current is changeable in 6 steps – 100nA, 1uA, 10uA, 100uA, 1mA, 10mA.

The compliance voltage is above 8.5V but slightly reduces to 7.5V at 10mA, however 10mA would usually only be used with more conductive samples where the compliance voltage is not so critical. Overall accuracy is better than 0.5% where the DVM receives greater than 1mV. For the mid ranges the accuracy is better than 0.3% The DVM has two ranges – high sensitivity up to 150mV and low range up to 1.25V. The unit is push button operated. The current is increased with the ‘INC’ button and decreased with the ‘DEC’ button.

Forward and reverse current can be selected using the ‘FWD’ and ‘REV’ buttons, which is a common way to check the validity of a measurement by checking the forward and reverse voltage values for consistency. When the battery mode is used, the unit returns to standby automatically to save power and turns off altogether after some period of inactivity.

The automatic time to return to standby is 70 seconds with low current and with the 3 highest currents 40 seconds. This is because the lower current ranges are used with higher impedance which can take longer to settle, and the higher currents drain the power faster. The unit can be zeroed to remove any offset by pressing the Standby button when the unit is already in Standby.

The HM21 includes on-board non-volatile memory so that fifty measurements can be stored in the unit and then downloaded to a PC later. When connected to a PC using the included software, the HM21 can save the data, or bulk resistivity values (ohms-cm) can be calculated. If the HM21 is connected to a PC using the software, the unit can be operated via the user interface which is an illustration of the HM21 on the computer screen. Clicking the “save” button on the computer screen saves the data to the PC.

Files are stored in the CSV format which opens automatically in Excel. The HM21 reads-out directly in sheet resistance (ohms-per-square) without using a PC or the software.

Downloads

We Recommend

The Multiposition Wafer Probe with the RM3000 Test Unit features high accuracy, an excellent range, and many features which simplify the four point probing measurement:

Multiposition Wafer Probe combined with the RM3000 Test Unit.

Four-Point-Probes is a division of Bridge Technology. To request further information please call Bridge Technology at (480) 219-9007 or send e-mail to Joshua Bridge at: sales@bridgetec.com